PV series Jaw Crusher is our newly research and developed type Jaw Crusher which combines many years practical experience,absoebing advanced technology and adopting advanced design instrumentalities. The crusher can crush various materials less than 250mpa compressive strength. The crusher is widely applied in various industries including mining, smelt, building materials, highway, railway, water conservancy, chemical industry, etc. lt is suitable for the primary crushing of various ores and rocks, like limestone iron ore, basalt, granite, etc.

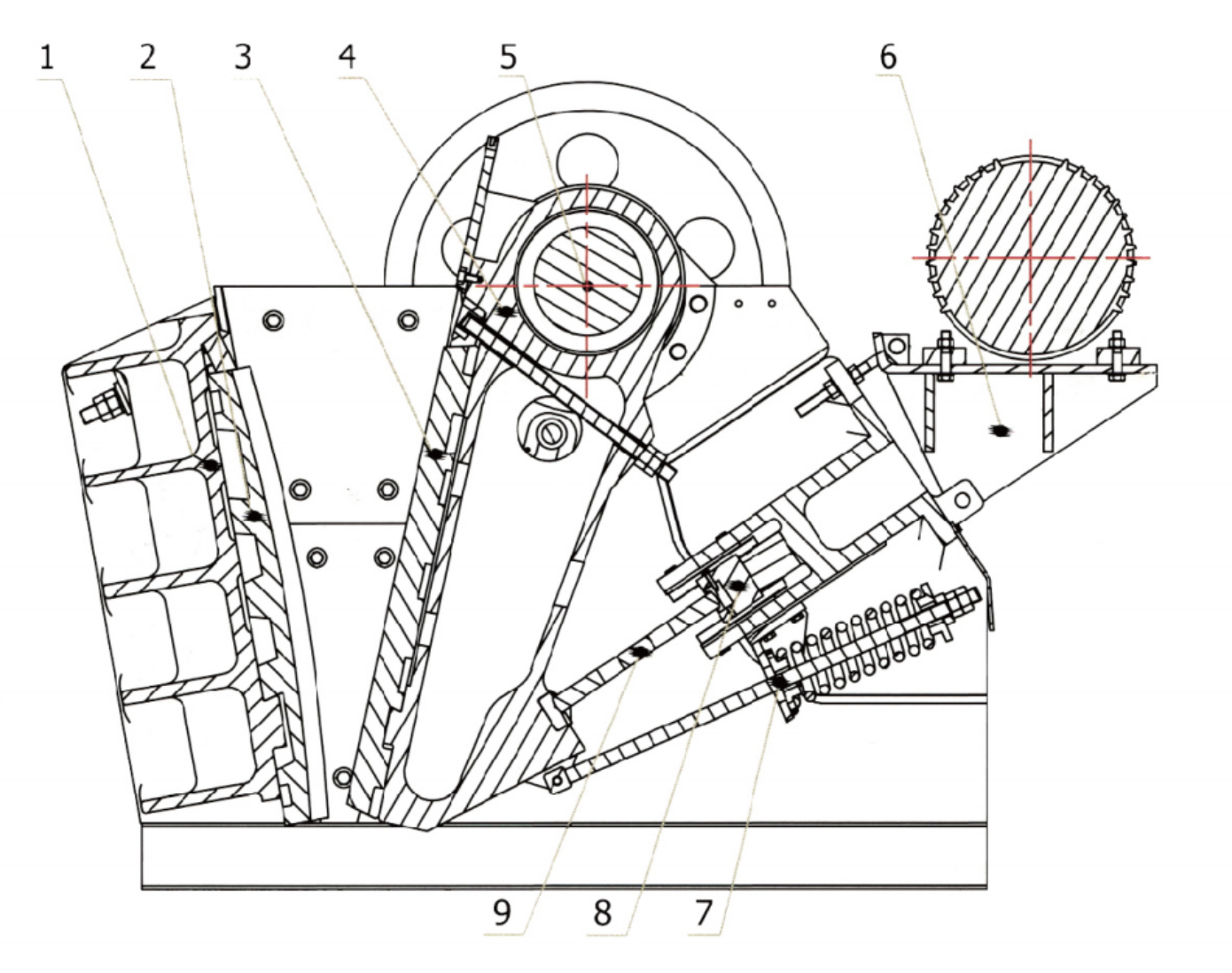

1、Frame Part

2、Fixed Jaw Plate

3、Swing Jaw Plate

4、Jaw stock

5、Eccentric Shaft

6、Motor Seat

7、Tension Rod+Spring Section

8、Toggle Seat

9、Toggle Plate

1、Special V-type Chamber design, achieving large stroke, better crushing perormance and capacity, as well as high crushing efficiency offering up to a 30% increase in performance over the PE range.

2、Adopts entirely welding structure frame. lt has advantages of strong rigidity, light weight, low consumption, convenient installation,etc.

3、Discharge port adjusted conveniently, using rotary screw rod to control the wedge thickness mechanically, and then adjiust thedischarge opening size, it helps to achieve convenient adjustment and wider adjusting scope.Motor attached on machine frame, saving installing space.

Technical Data Sheet

| Model | Power(kw) | Max.feeding(mm) | Weight(Inclmotor)(t) | O.S.S(mm) | Capacity(t/h) | Eccentric shaft speed(r/min) | Feed opening (mm) |

| PV710 | 110 | 600 | 17.1 | 110-210 | 155-305 | 270 | 710x1100 |

| PV912 | 132/160 | 800 | 39.3 | 155-250 | 238-470 | 240 | 900x1200 |

| PV690 | 75 | 500 | 14 | 100-160 | 125-200 | 270 | 600x900 |

Overall Dimension

| Model | A | B | C | D | E | F | G | H | I |

| PV710 | 1920 | 1650 | 1380 | 1606 | 1200 | 3238 | 2500 | 2376 | 1776 |

| PV912 | 2198 | 1898 | 1598 | 2296 | 1710 | 4456 | 3575 | 3411 | 2556 |

| PV690 | 1594 | 1374 | 1154 | 1607 | 1140 | 3190 | 2385 | 2271 | 1701 |